What to look for in a Small-Batch Producer

FDA approval is the goal of marketing strategy for medical industries. FDA approval is the goal of any marketing strategy in the medical industry.

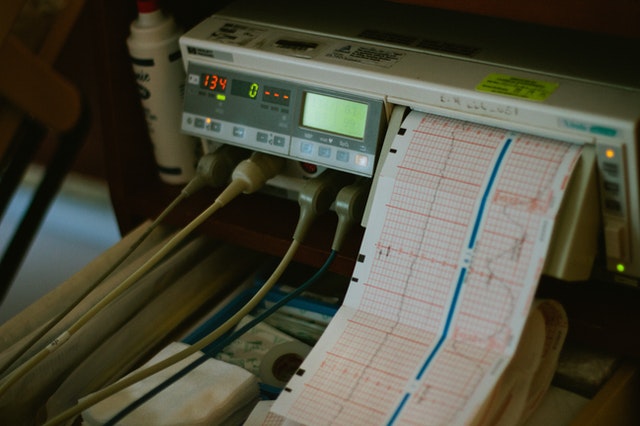

Low-Volume Production Manufacturing Methods

1. Additives for production

It is also called printing technology. It is also known as printing technology.

2. CNC Machining

The operation that begins with a piece of metal is a complete antithesis to rapid prototyping.

3. Injection Molding

This method is the most common for creating components and gadgets. It can be used to make components and gadgets from metal, glass or butyl.

Author Bio,

Search engine methods – The one-stop shop to get SEO, PPC, and SMM services. SearchEngineWays offers international platforms that offer User Engaged Native Article writing and Real Outreach Guest Post backlinks. This will increase your website traffic, brand visibility and search engine results page improvements for your target keywords.